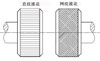

鋁型材擠壓模有分流組合模、平面模兩種結構形式。分别見圖1,圖2。模具的尺寸見表1。

表 1 鋁型材擠壓模具尺寸

擠壓機 (MN) | 模具輪廓 | 擠 壓 筒 内 徑 | |||||

70 ~100 | >100 ~130 | >130 ~160 | >160 ~180 | >180 ~200 | >200 ~260 | ||

| <4.9 | D | 120 140 | |||||

| H1 | 140 | ||||||

| H2 | 120 | ||||||

| <4.9 | D | 140 160 180 | |||||

| H1 | 140 160 180 | ||||||

| H2 | 100 120 | ||||||

| <4.9 | D | 180 200 220 | |||||

| H1 | 180 200 | ||||||

| H2 | 110 130 | ||||||

| <4.9 | D | 220 240 | |||||

| H1 | 180 200 | ||||||

| H2 | 110 130 | ||||||

| <4.9 | D | 220 240 | |||||

| H1 | 200 | ||||||

| H2 | 140 150 | ||||||

| <4.9 | D | 240 300 360 | |||||

| H1 | 200 220 240 | ||||||

| H2 | 180 200 | ||||||

注: ① D≥1.45~1.60Dm,Dm 為鋁型材的最大外接圓直徑。

② 在保證 H1、H2 的基礎上,允許采用其它結構。

3.1 制造鋁型材擠壓模具用鋼

3.1.1 模具用鋼采用電渣重熔鋼或爐外精煉鋼,允許采用電爐鋼。

3.1.2 模具用 4Cr5MoSiVi,模墊用 5CrNiMo,鋼的化學成分及其它技術條件應符合 GB 1299 的要求。

3.2 鋁型材擠壓模具的模坯

3.2.1 模坯尺寸應符合 GB 908 的要求。

3.2.2 模坯應按 GB 231 的方法測定布氏硬度,并滿足 GB 1299 的要求。

3.2.3 模坯的心部與邊部的沖擊值 αk 比應 ≥ 0.80。

3.3 鋁型材擠壓模具的制造精度

鋁型材擠壓模具的制造精度優先滿足模具設計圖的要求,若無特殊要求應符合表 1 的規定。

3.4 鋁型材擠壓模具的熱處理

3.4.1 鋁型材擠壓模具的熱處理設備必須有防氧化措施,并優先采用真空爐。

3.4.2 模具淬火後必須及時充分回火。

3.4.3 模具熱處理後應按 GB 230 檢驗硬度,模具的硬度範圍 48~52 HRC,模墊硬度範圍 44~49 HRC。按 GB 224 檢驗脫碳層深度 < 0.2 mm。有特殊要求按供需雙方協議執行。

3.5 鋁型材擠壓模具的表面處理

3.5.1 為提高模具的耐磨性和工作帶的表面質量,可選擇滲氮、氮碳共滲或多元共滲等表面處理工藝。

3.5.2 為延長模具壽命提高模具表面硬度,減少應力集中應在模具使用一段時間後再次進行表面處理。

3.5.3 鋁型材擠壓模具經表面處理後應符合:

硬度800~1100 HV;擴散層厚度 0.075~0.15 mm。

4.1 鋁型材擠壓模具的驗收按本技術條件 4.3~4.4 條規定進行。

4.2 鋁型材擠壓模具的制造精度的檢驗工具或手段應符合表 2 的要求。

4.3 鋁型材擠壓模具的綜合質量應在正常的擠壓工藝下用試模方法來檢驗。試模擠壓出的鋁型材質量,建築型材符合 GB 5237 、工業型材符合 GB 6892 或鋁型材圖要求的模具為合格產品。

表 2

| 序号 | 項 目 | 精度 | 檢驗工具與手段 |

| 1 | 模具外徑 D mm | 0 -0.25 | 卡尺 |

| 2 | 模具厚度 H1、H2 mm | +0.10 0 | 卡尺 |

| 3 | 模具端面平行度 | 6級 GB 1184 | 千分表 |

| 4 | 止口深度 mm | ±0.15 | 深度尺 |

| 5 | 止口對外圓的同軸度 | 8級 GB 1184 | 千分表 |

| 6 | 平面模導流口尺寸 | 15級 GB 1184 | 卡尺 |

| 7 | 平面模導流口底面粗糙度 | 0.8 μm | 粗糙度對比塊 |

| 8 | 分流組合模分流孔尺寸 | m級 GB/T 1804 | 卡尺 |

| 9 | 分流組合模分流孔粗糙度 | 1.6 μm | 粗糙度對比塊 |

| 10 | 模孔 mm | 0 -0.08 | 千分尺、量塊、卡尺 |

| 11 | 工作帶長度 mm | ±0.2 | 卡尺 |

| 12 | 工作帶粗糙度 | 0.4 μm | 粗糙度對比塊 |

| 13 | 工作帶垂直度 | ±15’ | 三維測量儀,允許采用間接方法來檢驗 |

| 14 | 凹、凸模的同軸度 | 13級 GB 1184 | 卡尺 |

Taper keys of keyways

Hexalobular internal driving feature for bolts and screws

Fasteners-Ends of parts with external thread(ISO 4753:2011, MOD)

Fasteners - Bolts, screws and studs - Nominal lengths and thread lengths (ISO 888:2012, MOD)

Countersinks for countersunk head screws

Connections with waisted stud - Tape classification

Flared couplings - Flared end

Hexalobular internal driving feature for bolts and screws

Knurl

Drill diameter for use prior to tapping screw threads

Square and rectangular keyways

Woodruff keyways

General purpose bolts and screws - Radius under the head

Center holes

Rivet Shank Diameters (Except Blind Rivets) [ISO 1051:1999]

Stress area and bearing area for threaded fasteners

Countersunk flat head screws - Part2: Penetration depth of cross recesses

Offset cruciform recess fro rotary fastening devices

Clearance holes for rivets

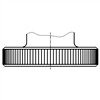

Hot-rolled channel steel

Hexagon lobuar for fasteners - Type E

Fasteners - Clearanc holes for bolts and screws

Fasteners - Split pin holes and wire holes (ISO 7378:1983)

Countersunk head screws - Head configuration and gauging

Cross recesses for screws

Fastners - Widths across flats of hexagon products

Self-tapping screws for metric ISO threads - Part 2: Guide values for hole diameters

Thread run-outs and thread undercuts

Tapping screw connections - Guideline values for core hole diameters and use

12 point socket for bolts and screws

60° centre holes - Types R. A. B. and C

Thread rolling screws for ISO metric thread guidelinge values for hole diameters

Thread ends and lengths of projection of bolt ends for metric ISO threads according to DIN 13

Knurle

Connections for hydraulic fluid power and general use - Ports and stud ends with ISO 261 metric threads and O-ring sealing - Part 1: Ports with truncated housing for O-ring

Hexalobular internal driving feature for bolts and screws

Connections for general use and fluid power - Ports and stud ends with ISO 228-1 threads with elastomeric or metal-to-metal sealing - Part 1: Threaded ports

Dimensioning and indication of knurling

Fasteners—Ends of parts with external ISO metric thread

Connections for general use and fluid power - Ports and stud ends with ISO 228-1 threads with elastomeric or metal-to-metal sealing - Part 4: Stud ends for general use only with metal-to-metal sealing (type B)

Hexalobular internal driving feature for bolts and screws

Geometrical product specifications (GPS) - Indication of surface texture in technical product documentation

General purpose bolts and screws─Metric series─Radii under the head

Rivet shank diameters

Aerospace - Spline drives - Wrenching configuration - Metric series

Connections for general use and fluid power - Ports and stud ends with ISO 261 threads with elastomeric or metal-to-metal sealing - Part 1: Threaded ports

Connections for general use and fluid power - Ports and stud ends with ISO 261 threads with elastomeric or metal-to-metal sealing - Part 2: Stud ends with elastomeric sealing (type E)

Connections for general use and fluid power - Ports and stud ends with ISO 261 threads with elastomeric or metal-to-metal sealing - Part 3: Stud ends with metal-to-metal sealing (type B)

Connections for general use and fluid power - Ports and stud ends with ISO 725 threads and O-ring sealing - Part 3: Light-duty (L series) stud ends

Fasteners—Surface discontinuities— Part2:Nuts

Countersunk flat hed screws—Part 2:Penetration depth of cross recesses

Fasteners—Surface discontinuities— Part1:Bolts,screws and studs for general requirements

Fasteners—Surface discontinuities— Part3:Bolts,screw and studs for special requirements

Internal drive, offset cruciform recess (Torq-Set) for rotary fastening devices. Metric series

Fasteners—Thread undercuts for external metric ISO

Cross recessed-H type

Cross recessed-Z type

Countersunk head screws—Head configuration and guaging

Fasteners—Hexagon products—Widths across flats

Fasteners─Clearance holes for bolts and screws

Thread run-out for fasteners with thread in accordance with ISO 261 and ISO 262

Copper tubes of circular section - Dimensions

Hexalobular internal driving feature for bolts and screws

Stress area and bearing area for threaded fasteners

General purpose bolts and screws - Metric series -- Radii under the head

Straight cylindrical involute splines -- side fit -- Generalities, dimensions and inspection

Knurling

Automatic Cold Header - Hole Size

Recess Dimensions for Flat 82° Countersunk Head Screws

Dimensions of Threads and Points for Types BF and BT Thread-Cutting Tapping Screws

Dimensions of Threads and Points for Type D, F, G, and T Thread-Cutting Tapping Screws

Dimensions of Type TRS Tapping Screws

Standard Test-Plate Thickness and Hole Sizes for Drive-Test Inspection of Tapping Screws

Dimensions of Alternate Styles of Points for Thumb and Wing Screws

Hot rolled flat steel bars and steel wide flats for general purposes - Dimensions and tolerances on shape and dimensions

Cold Rolled Uncoated and Zinc or Zinc-Nickel Electrolytically Coated Low Carbon and High Yield Strength Steel Flat Products for Cold Forming - Tolerances on Dimensions and Shape

Aerospace series - Installation holes for inserts, screw thread, helical coil, self-locking - Design standard

Countersunk head screws - Head configuration and gauging

Tapping rivats - Thread and end

Fasteners - Clearanc holes for bolts and screws

Cross Recesses For Screws

Standard Test-Plate Thickness and Hole Sizes for Drive-Test Inspection of Tapping Screws

Dimensions of Threads and Points for Types BF and BT Thread-Cutting Tapping Screws

Dimensions of Threads and Points for Type D, F, G, and T Thread-Cutting Tapping Screws

Type TRS Tapping Screws

Dimensions of Hexagon Sockets [Table 18]

![Body and grip lengths for socket head cap screws [Table 4]](https://imgcc.164580.com/upload/48/pic/2021/05/27/1622102178590886964.jpg)

Body and grip lengths for socket head cap screws [Table 4]

Metic threads and points for tapping screws

![Type BF and BT, Thread Cutting Tapping Screws [Table 7]](https://imgcc.164580.com/upload/48/standard/2020/06/05/1591322143016742879.jpg)

Type BF and BT, Thread Cutting Tapping Screws [Table 7]

![Type D,F,G and Type T Thread Cutting Tapping Screws [Table 8]](https://imgcc.164580.com/upload/48/standard/2020/06/05/1591326271806674189.jpg)

Type D,F,G and Type T Thread Cutting Tapping Screws [Table 8]

Aerospace series - Six lobe recess - Dimensions and tolerances

Threaded ends of fitting