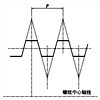

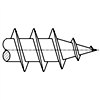

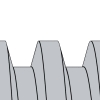

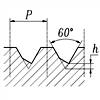

30°楔形防松螺紋的牙型應符合下圖的規定(粗實線)。

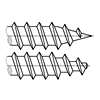

外螺紋有普通螺紋(M)和MJ螺紋兩種,其牙型應分别符合GB/T 192和GJB 3.1A的規定。

30°楔形防松螺紋有兩種配合公差:精密級(4H/4h)和中等級(6H/6g)。

30°楔形防松内螺紋斜面大徑和斜面小徑與其中徑具有相同的公差值(4H或6H)。

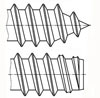

30°楔形防松内螺紋公差帶位置見圖2(剖面線部分)。

精密級和中等級内螺紋塗鍍前的公差和直徑極限尺寸應分别符合表1和表2的規定。

表1和表2内的斜面大徑和斜面小徑數值是牙底斜面與牙側延長相交所形成的理論直徑值。

本标準不規定塗鍍後内螺紋的直徑極限尺寸及其檢驗方法。

M外螺紋的基本尺寸和公差(4h和6g)應分别符合GB/T 196和GB/T 197的規定。

MJ外螺紋的基本尺寸和公差(4h和6g)應符合GJB 3.1A的規定。

注:在用戶允許條件下,内螺紋斜面小徑的最小值可以小于表1和表2的規定下限。

表1 精密級(4H)内螺紋的塗鍍前公差和直徑極限尺寸

螺紋規格 | 斜面大徑D | 斜面小徑D5 | 牙頂小徑D1 | 斜面大徑和斜面小徑公差 TD | 牙頂小徑公差TD1 | ||||

公稱 直徑 | 螺距 | max | min | max | min | max | min | ||

5 | 0.8 | 5.154 | 5.074 | 4.711 | 4.631 | 4.404 | 4.304 | 0.08 | 0.1 |

6 | 1 | 6.188 | 6.093 | 5.646 | 5.551 | 5.239 | 5.119 | 0.095 | 0.12 |

7 | 1 | 7.188 | 7.093 | 6.646 | 6.551 | 6.239 | 6.119 | 0.095 | 0.12 |

8 | 1 | 8.188 | 8.093 | 7.646 | 7.551 | 7.239 | 7.119 | 0.095 | 0.12 |

8 | 1.25 | 8.216 | 8.116 | 7.543 | 7.443 | 7.03 | 6.894 | 0.1 | 0.136 |

10 | 1 | 10.188 | 10.093 | 9.646 | 9.551 | 9.239 | 9.119 | 0.095 | 0.12 |

10 | 1.25 | 10.216 | 10.116 | 9.543 | 9.443 | 9.03 | 8.894 | 0.1 | 0.136 |

10 | 1.5 | 10.251 | 10.139 | 9.46 | 9.348 | 8.809 | 8.657 | 0.112 | 0.152 |

12 | 1.25 | 12.228 | 12.116 | 11.565 | 11.453 | 11.020 | 10.884 | 0.112 | 0.136 |

12 | 1.5 | 12.257 | 12.139 | 11.46 | 11.342 | 10.815 | 10.663 | 0.118 | 0.152 |

12 | 1.75 | 12.287 | 12.162 | 11.375 | 11.25 | 10.591 | 10.421 | 0 125 | 0.17 |

14 | 1.5 | 14.257 | 14.139 | 13.46 | 13.342 | 12.815 | 12.663 | 0.118 | 0.152 |

14 | 2 | 14.318 | 14.186 | 13.3 | 13.168 | 12.424 | 12.235 | 0.132 | 0.189 |

16 | 1.5 | 16.257 | 16.139 | 15.46 | 15.342 | 14.815 | 14.663 | 0.118 | 0.152 |

16 | 2 | 16.318 | 16.186 | 15.3 | 15.168 | 14.424 | 14.235 | 0.132 | 0.189 |

18 | 1.5 | 18.257 | 18.139 | 17.46 | 17.342 | 16.815 | 16.663 | 0.118 | 0.152 |

18 | 2 | 18.318 | 18.186 | 17.3 | 17.168 | 16.424 | 16.235 | 0.132 | 0.189 |

18 | 2.5 | 18.372 | 18.232 | 17.117 | 16.977 | 16 | 15.776 | 0.14 | 0.224 |

20 | 1.5 | 20.257 | 20.139 | 19.46 | 19.342 | 18.815 | 18.663 | 0.118 | 0.152 |

20 | 2 | 20.318 | 20.186 | 19.3 | 19.168 | 18.424 | 18.235 | 0.132 | 0.189 |

20 | 2.5 | 20.372 | 20.232 | 19.117 | 18.977 | 18 | 17.776 | 0.14 | 0.224 |

22 | 1.5 | 22.257 | 22.139 | 21.46 | 21.342 | 20.815 | 20.663 | 0.118 | 0.152 |

22 | 2 | 22.318 | 22.186 | 21.3 | 21.168 | 20.424 | 20.235 | 0.132 | 0 189 |

22 | 2.5 | 22.372 | 22.232 | 21.117 | 20.977 | 20 | 19.776 | 0.14 | 0.224 |

24 | 1.5 | 24.264 | 24.139 | 23.46 | 23.335 | 22.822 | 22.67 | 0.125 | 0.152 |

24 | 2 | 24.326 | 24.186 | 23.3 | 23.16 | 22.432 | 22.243 | 0.14 | 0.189 |

24 | 3 | 24.448 | 24.278 | 22.959 | 22.789 | 21.565 | 21.313 | 0.17 | 0.252 |

27 | 1.5 | 27.264 | 27.139 | 26.46 | 26.335 | 25.822 | 25.67 | 0.125 | 0.152 |

27 | 2 | 27.326 | 27.186 | 26.3 | 26.16 | 25.432 | 25.243 | 0.14 | 0.189 |

27 | 3 | 27.448 | 27.278 | 25.959 | 25.789 | 24.565 | 24.313 | 0.17 | 0.252 |

30 | 1.5 | 30.264 | 30.139 | 29.46 | 29.335 | 28.822 | 28.67 | 0.125 | 0.152 |

30 | 2 | 30.326 | 30.186 | 29.3 | 29.16 | 28.432 | 28.243 | 0.14 | 0.189 |

30 | 3.5 | 30.505 | 30.325 | 28.765 | 28.585 | 27.153 | 26.869 | 0.18 | 0.284 |

33 | 2 | 33.326 | 33.186 | 32.3 | 32.16 | 31.432 | 31.243 | 0.14 | 0.189 |

33 | 3.5 | 33.505 | 33.325 | 31.765 | 31.585 | 30.153 | 29.869 | 0.18 | 0.284 |

36 | 2 | 36.326 | 36.186 | 35.3 | 35.16 | 34.432 | 34.243 | 0.14 | 0.189 |

36 | 3 | 36.448 | 36.278 | 34.959 | 34.789 | 33.565 | 33.313 | 0.17 | 0.252 |

36 | 4 | 36.561 | 36.371 | 34.591 | 34.401 | 32.703 | 32.403 | 0.19 | 0.3 |

39 | 2 | 39.326 | 39.186 | 38.3 | 38.16 | 37.432 | 37.243 | 0. 14 | 0.189 |

39 | 3 | 39.448 | 39.278 | 37.959 | 37.789 | 36.565 | 36.313 | 0.17 | 0.252 |

39 | 4 | 39.561 | 39.371 | 37.591 | 37.401 | 35.703 | 35.403 | 0.19 | 0.3 |

注:螺紋牙側位置決定螺紋中徑的大小;螺紋中徑決定牙底斜面的長短。在30°牙側角和斜面傾角條件下,斜面大徑和斜面小徑與螺紋中徑的數學關系為D2=2D-D5-0.866 025 404P。 | |||||||||

表2 中等級(6H)内螺紋塗鍍前的公差和直徑極限尺寸

螺紋規格 | 斜面大徑D | 斜面小徑D5 | 牙頂小徑D1 | 斜面大徑和斜面小徑公差 TD | 牙頂小徑公差TD1 | ||||

公稱 直徑 | 螺距 | max | min | max | min | max | min | ||

10 | 1.5 | 10.269 | 10.089 | 9.428 | 9.248 | 8.893 | 8.657 | 0.18 | 0.236 |

12 | 1.5 | 12.279 | 12.089 | 11.432 | 11.242 | 10.899 | 10.663 | 0.19 | 0.236 |

12 | 1.75 | 12.303 | 12.103 | 11.332 | 11.132 | 10.686 | 10.421 | 0.2 | 0.265 |

14 | 1.5 | 14.279 | 14.089 | 13.432 | 13.242 | 12.899 | 12.663 | 0.19 | 0.236 |

14 | 2 | 14.33 | 14.118 | 13.244 | 13.032 | 12.535 | 12.235 | 0.212 | 0.3 |

16 | 1.5 | 16.279 | 16.089 | 15.432 | 15.242 | 14.899 | 14.663 | 0.19 | 0.236 |

16 | 2 | 16.33 | 16.118 | 15.244 | 15.032 | 14.535 | 14.235 | 0.212 | 0.3 |

18 | 1.5 | 18.279 | 18.089 | 17.432 | 17.242 | 16.899 | 16.663 | 0.19 | 0.236 |

18 | 2 | 18.33 | 18.118 | 17.244 | 17.032 | 16.535 | 16.235 | 0.212 | 0.3 |

18 | 2.5 | 18.372 | 18.148 | 17.033 | 16.809 | 16.131 | 15.776 | 0.224 | 0.355 |

20 | 1.5 | 20.279 | 20.089 | 19.432 | 19.242 | 18.899 | 18.663 | 0.19 | 0.236 |

20 | 2 | 20.33 | 20.118 | 19.244 | 19.032 | 18.535 | 18.235 | 0.212 | 0.3 |

20 | 2.5 | 20.372 | 20.148 | 19.033 | 18.809 | 18.131 | 17.776 | 0.224 | 0.355 |

22 | 1.5 | 22.279 | 22.089 | 21.432 | 21.242 | 20.899 | 20.663 | 0.19 | 0.236 |

22 | 2 | 22.33 | 22.118 | 21.244 | 21.032 | 20.535 | 20.235 | 0.212 | 0.3 |

22 | 2.5 | 22.372 | 22.148 | 21.033 | 20.809 | 20.131 | 19.776 | 0.224 | 0.355 |

24 | 2 | 24.342 | 24.118 | 23.248 | 23.024 | 22.543 | 22.243 | 0.224 | 0.3 |

24 | 3 | 24.442 | 24.177 | 22.852 | 22.587 | 21.713 | 21.313 | 0.265 | 0.4 |

27 | 2 | 27.342 | 27.118 | 26.248 | 26.024 | 25.543 | 25.243 | 0.224 | 0.3 |

27 | 3 | 27.442 | 27.177 | 25.852 | 25.587 | 24.713 | 24.313 | 0.265 | 0.4 |

30 | 2 | 30.342 | 30.118 | 29.248 | 29.024 | 28.543 | 28.243 | 0.224 | 0.3 |

30 | 3.5 | 30.487 | 30.207 | 28.629 | 28.349 | 27.319 | 26.869 | 0.28 | 0.45 |

33 | 2 | 33.342 | 33.118 | 32.248 | 32.024 | 31.543 | 31.243 | 0.224 | 0.3 |

33 | 3.5 | 33.487 | 33.207 | 31.629 | 31.349 | 30.319 | 29.869 | 0.28 | 0.45 |

36 | 3 | 36.442 | 36.177 | 34.852 | 34.587 | 33.713 | 33.313 | 0.265 | 0.4 |

36 | 4 | 36.536 | 36.236 | 34.431 | 34.131 | 32.878 | 32.403 | 0.3 | 0.475 |

39 | 3 | 39.442 | 39.177 | 37.852 | 37.587 | 36.713 | 36.313 | 0.265 | 0.4 |

39 | 4 | 39.536 | 39.236 | 37.431 | 37.131 | 35.878 | 35.403 | 0.3 | 0.475 |

中等級公差隻用于螺距不小于1.5mm的螺紋規格。 注:螺紋牙側位置決定螺紋中徑的大小;螺紋中徑決定牙底斜面的長短。在30°牙側角和斜面傾角條件下,斜面大徑和斜面小徑與螺紋中徑的數學關系為D2=2D-D5-0.866 025 404P。 | |||||||||

Miniature screw threads : Profiles , general plan and basic dimensions

General purpose metric screw threads - Tolerances

The blank diameters for rolling general purpose metric screw threads

Dryseal pipe threads with the thread angle of 60 degrees

Internal thread for wire thread inserts

Buttress Thread with the Flank Angles of 3 and 30 Degrees - Part 1: Profiles

Metric threads where pressure-tight joints are made on the threads

General purpose metric screw threads - Limits of sizes

Unified screw threads - General plan

Trapezoidal screw threads - Part 1: Profiles

General purpose metric screw threads - The plan for pipe systems

General purpose metric screw threads-Basic profile(ISO 68-1:1998, MOD)

General purpose metric screw threads - Basic dimenslons

General purpose metric screw threads - Limit deviations

General purpose metric screw threads - Preferable plan

General purpose metric screw threads - Limits of sizes for the screw threads of medium quality and preferable plan

General purpose metric screw threads - Limits of sizes for the screw threads of coarse quality and preferable plan

Tapping screws thread

Pipe Threads with 55 Degree Thread Angle where Pressure-Tight Joints are not Made on the Threads

Pipe threads with 55 degree thread angle where pressure-tight joints are made on the threads一 Parallel internal and taper external threads(eqv ISO 7-1:1994)

Pipe threads with 55 degree thread angle where pressure-tight joints are made on the threads一 Taper internal and external threads(eqv ISO 7-1:1994)

The interference-fit threads

Run-outs, undercuts and chamfers for general purpose metric screw threads (ISO 3508:1976 / ISO 4755:1983)

The threads for transition fit

Pipe threads where pressure-tight joints are made on the threads

Screws thread shanks for thread forming screw-Metric coarse thread series

Specification for wood screws

Metric triangle lock with thread end

Metric Self-tapping Thread End

Whitworth pipe threads for pipe unions

Plastic threads

Threads and thread ends for tapping screws

ISO - Metric Trapezoidal Screw Threads

Thread and thread ends for wood screws

Bolted Connections with Reduced Shank; Metric Thread with Large Clearence, Nominal Dimensions and Limits

Aerospace - Lead and runout threads - Part 1: Rolled external threads

ISO metric trapezoidal screw threads - Basic and design profiles

ISO general purpose metric screw threads - Tolerances - Part 1: Principles and basic data

Fasteners─Bolts,screws and studs─Nominal lengths and thread lengths

ISO inch screw threads─Basic dimensions

Pipe threads where pressure-tight joints are not made on the threads

Tapping Screws Thread

ISO general purpose metric screw threads - General plan

ISO general purpose metric screw threads — Selected sizes for screws, bolts and nuts

Limits of sizes for general purpose external and internal screw threads

Deviations for constructional screw threads

Pipe threads where pressure-tight joints are made on the threads - Part 1: Dimensions, tolerances and designation

ISO general-purpose metric screw threads─Basic dimensions

HA Thread [Figure 2]

HB Thread [Figure 4]

Symmetrical thread HC [Figure 4]

Asymmetrical thread HD [Figure 6]

Tapping Screw Threads and Ends

Limit gauges for metric screw threads

Tapping screw threads and ends

Taper pipe threads

Limits of sizes and tolerances for metric coarse screw threads

Tapping Screw Threads and Ends

Locking Thread with 30° wedge ramp

The bar diameters for rolling general purpose screw threads

Special kind of fine screw for optical instruments

Dimensions of Threads and Points for Type AB and Type ABR Thread-forming Screws

Dimensions of Threads and Points for Type B and BP Thread-Forming Tapping Screws

Dimensions of Threads and Points for Type A Thread-Forming Tapping Screws

Thread Lengths for Type A, AB, B, BF, BP and BT Tapping Screws

Thread Lengths for Type C, D, F, G, T and TRS Tapping Screws

![Lag screw threads [Table 16]](https://imgcc.164580.com/upload/48/standard/2012/02/03/1328254371610499842.jpg)

Lag screw threads [Table 16]

AB self-tapping teeth

self-tapping teeth-B

Self-tapping teeth-BF

Triangle lock self-tapping teeth--D、F、G

Threaded rods(inch series) (A307, F1554, A193, CRES,F593,F468)

![Wood thread [Table 1]](https://imgcc.164580.com/upload/48/standard/2011/07/29/1311927213993228307.jpg)

Wood thread [Table 1]

![Thread and body dimeters for wood screws [Table 1]](https://imgcc.164580.com/upload/48/standard/2024/12/23/1734937527164073998.jpg)

Thread and body dimeters for wood screws [Table 1]

![Wood thread [Table 1]](https://imgcc.164580.com/upload/48/standard/2011/04/29/1304063562598941856.jpg)

Wood thread [Table 1]

Pipe threads where pressure tight joints are made on the threads - Part 1 : Taper external threads and parallel internal threads - Dimensions, tolerances and designation

US triangle lock thread-S type

Metric triangle lock thread-S type

Metric triangle lock thread-C type

Metric triangle lock thread-B type

Metric triangle lock thread-P type

![Thread and point details for Type Y thread cutting screws [TABLE 6]](https://imgcc.164580.com/upload/48/standard/2020/07/27/1595832347314908017.jpg)

Thread and point details for Type Y thread cutting screws [TABLE 6]

![Thread and point details for Type A threads [TABLE 23]](https://imgcc.164580.com/upload/48/standard/2020/07/27/1595832360911151243.jpg)

Thread and point details for Type A threads [TABLE 23]

Threaded insert, coated with precote 80 microcapsules recommended lengths

Screw Threads - UNJ Profile, Inch

Tapping thread for nylon lock

Screw Threads for Thread Forming Tapping Screws - Dimensions

ISO general purpose metric screw threads - General plan

Thread Lengths for Types A, AB, B, BF, BP, and BT Tapping Screws

Thread Lengths for Types C, D, F, G, T, and TRS Tapping Screws

Dimensions of Threads and Points for Types AB and ABR Thread-Forming Tapping Screws

Dimensions of Threads and Points for Type B and BP Thread-Forming Tapping Screws

Dimensions of Threads and Points for Type A Thread-Forming Tapping Screws