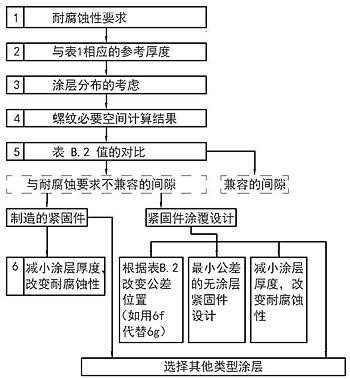

圖 B.4 耐腐蝕性和間隙的兼容性檢查

符合 GB/T 10125 規定的中性鹽霧試驗(NSS) 用于評估塗層體系的耐腐蝕性。

當要求對鹽霧試驗箱進行評估時,宜參照附錄C進行。

中性鹽霧試驗應在塗覆24 h後,在分揀、包裝和/或裝配前,對緊固件單獨進行。

按表1規定的試驗時間進行中性鹽霧試驗後,在基體金屬上不應有目測可見的金屬腐蝕(紅鏽)。

在評估耐腐蝕性時,不應考慮夾具與緊固件的接觸點。

表1 中性鹽霧試驗标準周期

中性鹽霧試驗持續時間(無紅鏽)/h | 塗層體系參考厚度a /μm |

240 | 4 |

480 | 5 |

600 | 6 |

720 | 8 |

960 | 10 |

塗層體系組成(僅包括底塗層、底塗層+表面塗層等)應在訂貨時規定。 | |

a. 參考厚度包括底塗層和表面塗層(如有),有或沒有六價鉻。耐腐蝕性應是接收的依據,參考厚度僅供參考。 | |

B.3塗層厚度的變化

緊固件鋅片塗層通常采用浸入-旋轉工藝,這導緻塗層厚度不均勻。

浸入-旋轉塗覆工藝會產生局部厚度顯著變化, 超出塗層厚度1/3t~1/2t。這個塗層厚度變量通常不會影響螺紋配合。宜謹慎考慮塗層厚度對螺紋基本中徑的影響,以滿足螺紋配合和量規擰入性。螺紋牙底塗層過厚通常不影響螺紋配合和量規擰入性,鋅片塗層工藝通常不會導緻螺紋牙頂塗層過厚。

注: 大規格、長尺寸或質量大的緊固件通常用挂裝塗覆。表B.1塗層厚度和螺紋基本中徑的幾何關系

塗層厚度 t | 螺紋基本中徑增加值 4ta |

3 | 12 |

4 | 16 |

5 | 20 |

6 | 24 |

8 | 32 |

10 | 40 |

12 | 48 |

a. 對應塗層厚度t所需的螺紋基本中徑基本偏差(間隙)增加值。 | |

表B.2 ISO米制螺紋間隙的理論極限值

螺距 P mm | 螺紋公稱直徑a d或D mm | 内螺紋 | 外螺紋 | |||

公差位置 G | 公差位置 g | 公差位置 f | 公差位置 e | |||

粗牙 | 細牙 | 最小間隙b μm | 最小間隙b μm | 最小間隙b μm | 最小間隙b μm | |

0.25 | 1和1.2 | / | +18 | -18 | / | / |

0.3 | 1.4 | / | +18 | -18 | / | / |

0.35 | 1.5和1.8 | / | +19 | -19 | -34 | / |

0.4 | 2 | / | +19 | -19 | -34 | / |

0.45 | 2.2和2.5 | / | +20 | -20 | -35 | / |

0.5 | 3 | / | +20 | -20 | -36 | -50 |

0.6 | 3.5 | / | +21 | -21 | -36 | -53 |

0.7 | 4 | / | +22 | -22 | -38 | -56 |

0.75 | 4.5 | / | +22 | -22 | -38 | -56 |

0.8 | 5 | / | +24 | -24 | -38 | -60 |

1 | 6和7 | 8和10 | +26 | -26 | -40 | -60 |

1.25 | 8 | 10和12 | +28 | -28 | -42 | -63 |

1.5 | 10 | 12~22 | +32 | -32 | -45 | -67 |

1.75 | 12 | / | +34 | -34 | -48 | -71 |

2 | 14和16 | 20~33 | +38 | -38 | -52 | -71 |

2.5 | 18、20和22 | / | +42 | -42 | -58 | -80 |

3 | 24和27 | 36~48 | +48 | -48 | -63 | -85 |

3.5 | 30和33 | / | +53 | -53 | -70 | -90 |

4 | 36和39 | 52~64 | +60 | -60 | -75 | -95 |

4.5 | 42和45 | / | +63 | -63 | -80 | -100 |

5 | 48和52 | / | +71 | -71 | -85 | -106 |

5.5 | 56和60 | / | +75 | -75 | -90 | -112 |

6 | 64 | / | +80 | -80 | -95 | -118 |

a. 螺紋公稱直徑作為信息給出,螺距是決定性特性。 b. 最小間隙對應于基本偏差。 | ||||||

B. 6.1 螺紋公差6g的螺栓示例

緊固件——符合GB/T 5782的螺栓M12,螺距1.75mm

耐腐蝕性要求——480h

查表1——參考塗層厚度:5μm

可能的分布(見B.3)——基本中徑上的最大厚度5μm+2.5μm,圓整至8μm

查表B.1(8μm×4)——32μm

查表B.2(6g)——最小間隙:34μm

結論:當計算值(32μm)小于或等于表B.2規定的最小間隙(34μm)時,對于塗覆前6g的螺紋,塗層厚度符合要求。

B. 6.2螺紋公差6g的螺釘示例

緊固件——符合GB/T5783的螺栓M6,螺距1mm

耐腐蝕性要求——600h

查表1——參考塗層厚度:6μm

可能的分布(見B.3)——基本中徑上的最大厚度6μm+3μm

查表B.1(9μm×4)——36μm

查表B.2(6g)——最小間隙:26μm

結論:計算值(36μm)超過表B.2規定的最小間隙(26μm)時,塗層厚度不符合要求。

B. 6.3 與B.6.2中相同的螺釘,螺紋公差6f

緊固件——符合GB/T5783的螺栓M6,螺距1mm

耐腐蝕性要求——600h

查表1——參考塗層厚度:6μm

可能的分布(見B.3)——基本中徑上的最大厚度6μm+3μm

查表B.1(9μm×4)——36μm

查表B.2(6f)——最小間隙:40μm

結論:計算值(36μm)小于表B.2規定的最小間隙(40μm),對于塗覆前為6f螺紋,塗層厚度符合要求。

Metallic and other inorganic coatings - Electrodeposited coatings of nickel, nickel plus chromium, copper plus nickel and of copper plus nickel plus chromium

Fasteners - Fundamentals of hydrogen embrittlement in steel fasteners

Metallic coatings - Hot dip galvanized coatings on fabricated iron and steel articles - Specifications and test methods

Fasteners - Hot dip galvanized coatings

Metallic coatings - Electrodeposited coatings of nickel

Chemical conversion coatings - Black oxide coating on iron and steel - Specification and test methods

Specifications of Zinc / Chromate coatings

Chromate conversion coatings on electroplated zinc and cadmium coatings

Metallic coatings - Electroplated coatings of zinc and zinc alloys on iron or steel with supplementary Cr(Vl)-free treatment

Metallic coatings - Hot dip galvanized coatings on fabricated iron and steel articles - Specifications and test methods

Fasteners - Non-electrolytically applied zinc flake coatings systems

Fasteners - Electroplated coating systems

Corrosion of metals and alloys - Corrosivity of atmospheres - Classification, determination and estimation

Fasteners—Hot dip galvanized coatings

Passivation of corrosion-resistant stainless-steel fasteners

Metallic coatings - Electrodeposited coatings of nickel

Chromate conversion coatings on electroplated zinc and cadmium coatings

Metallic coatings - Electroplated coatings of copper plus nickel plus chromium on iron or steel

Metallic and Other Inorganic Coatings - Electroplated Coatings of Zinc with Supplementary Treatments on Iron or Steel

Metallic and other inorganic coatings - Electrodeposited coatings of nickel, nickel plus chromium, copper plus nickel and of copper plus nickel plus chromium

Sherardizing of iron and steel articles

Aerospace series - Electrolytic silver plating of fasteners

Corrosion Protection of Metals - Electrodeposited Coatings of Zinc with Supplementary Treatment on Iron or Steel

Fasteners - surface discontinuities - nuts

Fasteners - Surface Discontinuities - Part 1: Bolts, Screws and Studs for General Requirements

Fasteners - Surface Discontinuities - Part 3: Bolts, Screws and Studs for Special Requirements

Water-based epoxy anticorrosive coatings

Electroplated coatings on threaded components - Part 1: Cadmium on Steel Components - Part 2: Zinc on Steel Components

Selection principle and thickness series for metallic and chemical coating

Specification for electroplated coatings of zinc on iron and steel

General specification for fastener aluminum coating for aircraft