| |

| 還沒有尺寸圖!

尺寸單位:

毫米(mm)/英寸(inch) |

滑動查看

| |

| 還沒有尺寸圖!

尺寸單位:

毫米(mm)/英寸(inch) |

滑動查看

螺距 P/mm | 基本偏差/μm | |||||||||

内螺紋 | 外螺紋 | |||||||||

G EI | H EI | a es | b es | c es | d es | e es | f es | g es | h es | |

0.2 | +17 | 0 | / | / | / | / | / | / | -17 | 0 |

0.25 | +18 | 0 | / | / | / | / | / | / | -18 | 0 |

0.3 | +18 | 0 | / | / | / | / | / | / | -18 | 0 |

0.35 | +19 | 0 | / | / | / | / | / | -34 | -19 | 0 |

0.4 | +19 | 0 | / | / | / | / | / | -34 | -19 | 0 |

0.45 | +20 | 0 | / | / | / | / | / | -35 | -20 | 0 |

0.5 | +20 | 0 | / | / | / | / | -50 | -36 | -20 | 0 |

0.6 | +21 | 0 | / | / | / | / | -53 | -36 | -21 | 0 |

0.7 | +22 | 0 | / | / | / | / | -56 | -38 | -22 | 0 |

0.75 | +22 | 0 | / | / | / | / | -56 | -38 | -22 | 0 |

0.8 | +24 | 0 | / | / | / | / | -60 | -38 | -24 | 0 |

1 | +26 | 0 | -290 | -200 | -130 | -85 | -60 | -40 | -26 | 0 |

1.25 | +28 | 0 | -295 | -205 | -135 | -90 | -63 | -42 | -28 | 0 |

1.5 | +32 | 0 | -300 | -212 | -140 | -95 | -67 | -45 | -32 | 0 |

1.75 | +34 | 0 | -310 | -220 | -145 | -100 | -71 | -48 | -34 | 0 |

2 | +38 | 0 | -315 | -225 | -150 | -105 | -71 | -52 | -38 | 0 |

2.5 | +42 | 0 | -325 | -235 | -160 | -110 | -80 | -58 | -42 | 0 |

3 | +48 | 0 | -335 | -245 | -170 | -115 | -85 | -63 | -48 | 0 |

3.5 | +53 | 0 | -345 | -255 | -180 | -125 | -90 | -70 | -53 | 0 |

4 | +60 | 0 | -355 | -265 | -190 | -130 | -95 | -75 | -60 | 0 |

4.5 | +63 | 0 | -365 | -280 | -200 | -135 | -100 | -80 | -63 | 0 |

5 | +71 | 0 | -375 | -290 | -212 | -140 | -106 | -85 | -71 | 0 |

5.5 | +75 | 0 | -385 | -300 | -224 | -150 | -112 | -90 | -75 | 0 |

6 | +80 | 0 | -395 | -310 | -236 | -155 | -118 | -95 | -80 | 0 |

8 | +100 | 0 | -425 | -340 | -265 | -180 | -140 | -118 | -100 | 0 |

表2 内螺紋小徑公差(TD1)

單位:微米 | |||||

螺距 P/mm | 公差等級 | ||||

4 | 5 | 6 | 7 | 8 | |

0.2 | 38 | / | / | / | / |

0.25 | 45 | 56 | / | / | / |

0.3 | 53 | 67 | 85 | / | / |

0.35 | 63 | 80 | 100 | / | / |

0.4 | 71 | 90 | 112 | / | / |

0.45 | 80 | 100 | 125 | / | / |

0.5 | 90 | 112 | 140 | 180 | / |

0.6 | 100 | 125 | 160 | 200 | / |

0.7 | 112 | 140 | 180 | 224 | / |

0.75 | 118 | 150 | 190 | 236 | / |

0.8 | 125 | 160 | 200 | 250 | 315 |

1 | 150 | 190 | 236 | 300 | 375 |

1.25 | 170 | 212 | 265 | 335 | 425 |

1.5 | 190 | 236 | 300 | 375 | 475 |

1.75 | 212 | 265 | 335 | 425 | 530 |

2 | 236 | 300 | 375 | 475 | 600 |

2.5 | 280 | 355 | 450 | 560 | 710 |

3 | 315 | 400 | 500 | 630 | 800 |

3.5 | 355 | 450 | 560 | 710 | 900 |

4 | 375 | 475 | 600 | 750 | 950 |

4.5 | 425 | 530 | 670 | 850 | 1060 |

5 | 450 | 560 | 710 | 900 | 1120 |

5.5 | 475 | 600 | 750 | 950 | 1180 |

6 | 500 | 630 | 800 | 1000 | 1250 |

8 | 630 | 800 | 1000 | 1250 | 1600 |

表3 外螺紋大徑公差(Td)

單位:微米 | |||

螺距 P/mm | 公差等級 | ||

4 | 6 | 8 | |

0.2 | 36 | 56 | / |

0.25 | 42 | 67 | / |

0.3 | 48 | 75 | / |

0.35 | 53 | 85 | / |

0.4 | 60 | 95 | / |

0.45 | 63 | 100 | / |

0.5 | 67 | 106 | / |

0.6 | 80 | 125 | / |

0.7 | 90 | 140 | / |

0.75 | 90 | 140 | / |

0.8 | 95 | 150 | 236 |

1 | 112 | 180 | 280 |

1.25 | 132 | 212 | 335 |

1.5 | 150 | 236 | 375 |

1.75 | 170 | 265 | 425 |

2 | 180 | 280 | 450 |

2.5 | 212 | 335 | 530 |

3 | 236 | 375 | 600 |

3.5 | 265 | 425 | 670 |

4 | 300 | 475 | 750 |

4.5 | 315 | 500 | 800 |

5 | 335 | 530 | 850 |

5.5 | 355 | 560 | 900 |

6 | 375 | 600 | 950 |

8 | 450 | 710 | 1180 |

表4 内螺紋中徑公差(TD2)

單位:微米 | |||||||

基本大徑 D/mm | 螺距 P/mm | 公差等級 | |||||

> | ≤ | 4 | 5 | 6 | 7 | 8 | |

0.99 | 1.4 | 0.2 | 40 | / | / | / | / |

0.25 | 45 | 56 | / | / | / | ||

0.3 | 48 | 60 | 75 | / | / | ||

1.4 | 2.8 | 0.2 | 42 | / | / | / | / |

0.25 | 48 | 60 | / | / | / | ||

0.35 | 53 | 67 | 85 | / | / | ||

0.4 | 56 | 71 | 90 | / | / | ||

0.45 | 60 | 75 | 95 | / | / | ||

2.8 | 5.6 | 0.35 | 56 | 71 | 90 | / | / |

0.5 | 63 | 80 | 100 | 125 | / | ||

0.6 | 71 | 90 | 112 | 140 | / | ||

0.7 | 75 | 95 | 118 | 150 | / | ||

0.75 | 75 | 95 | 118 | 150 | / | ||

0.8 | 80 | 100 | 125 | 160 | 200 | ||

5.6 | 11.2 | 0.75 | 85 | 106 | 132 | 170 | / |

1 | 95 | 118 | 150 | 190 | 236 | ||

1.25 | 100 | 125 | 160 | 200 | 250 | ||

1.5 | 112 | 140 | 180 | 224 | 280 | ||

11.2 | 22.4 | 1 | 100 | 125 | 160 | 200 | 250 |

1.25 | 112 | 140 | 180 | 224 | 280 | ||

1.5 | 118 | 150 | 190 | 236 | 300 | ||

1.75 | 125 | 160 | 200 | 250 | 315 | ||

2 | 132 | 170 | 212 | 265 | 335 | ||

2.5 | 140 | 180 | 224 | 280 | 355 | ||

22.4 | 45 | 1 | 106 | 132 | 170 | 212 | / |

1.5 | 125 | 160 | 200 | 250 | 315 | ||

2 | 140 | 180 | 224 | 280 | 355 | ||

3 | 170 | 212 | 265 | 335 | 425 | ||

3.5 | 180 | 224 | 280 | 355 | 450 | ||

4 | 190 | 236 | 300 | 375 | 475 | ||

4.5 | 200 | 250 | 315 | 400 | 500 | ||

45 | 90 | 1.5 | 132 | 170 | 212 | 265 | 335 |

2 | 150 | 190 | 236 | 300 | 375 | ||

3 | 180 | 224 | 280 | 355 | 450 | ||

4 | 200 | 250 | 315 | 400 | 500 | ||

5 | 212 | 265 | 335 | 425 | 530 | ||

5.5 | 224 | 280 | 355 | 450 | 560 | ||

6 | 236 | 300 | 375 | 475 | 600 | ||

90 | 180 | 2 | 160 | 200 | 250 | 315 | 400 |

3 | 190 | 236 | 300 | 375 | 475 | ||

4 | 212 | 265 | 335 | 425 | 530 | ||

6 | 250 | 315 | 400 | 500 | 630 | ||

8 | 280 | 355 | 450 | 560 | 710 | ||

180 | 355 | 3 | 212 | 265 | 335 | 425 | 530 |

4 | 236 | 300 | 375 | 475 | 600 | ||

6 | 265 | 335 | 425 | 530 | 670 | ||

8 | 300 | 375 | 475 | 600 | 750 | ||

表5 外螺紋中徑公差(Td2)

單位:微米 | |||||||||

基本大徑 d/mm | 螺距 P/mm | 公差等級 | |||||||

> | ≤ | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

0.99 | 1.4 | 0.2 | 24 | 30 | 38 | 48 | / | / | / |

0.25 | 26 | 34 | 42 | 53 | / | / | / | ||

0.3 | 28 | 36 | 45 | 56 | / | / | / | ||

1.4 | 2.8 | 0.2 | 25 | 32 | 40 | 50 | / | / | / |

0.25 | 28 | 36 | 45 | 56 | / | / | / | ||

0.35 | 32 | 40 | 50 | 63 | 80 | / | / | ||

0.4 | 34 | 42 | 53 | 67 | 85 | / | / | ||

0.45 | 36 | 45 | 56 | 71 | 90 | / | / | ||

2.8 | 5.6 | 0.35 | 34 | 42 | 53 | 67 | 85 | / | / |

0.5 | 38 | 48 | 60 | 75 | 95 | / | / | ||

0.6 | 42 | 53 | 67 | 85 | 106 | / | / | ||

0.7 | 45 | 56 | 71 | 90 | 112 | / | / | ||

0.75 | 45 | 56 | 71 | 90 | 112 | / | / | ||

0.8 | 48 | 60 | 75 | 95 | 118 | 150 | 190 | ||

5.6 | 11.2 | 0.75 | 50 | 63 | 80 | 100 | 125 | / | / |

1 | 56 | 71 | 90 | 112 | 140 | 180 | 224 | ||

1.25 | 60 | 75 | 95 | 118 | 150 | 190 | 236 | ||

1.5 | 67 | 85 | 106 | 132 | 170 | 212 | 265 | ||

11.2 | 22.4 | 1 | 60 | 75 | 95 | 118 | 150 | 190 | 236 |

1.25 | 67 | 85 | 106 | 132 | 170 | 212 | 265 | ||

1.5 | 71 | 90 | 112 | 140 | 180 | 224 | 280 | ||

1.75 | 75 | 95 | 118 | 150 | 190 | 236 | 300 | ||

2 | 80 | 100 | 125 | 160 | 200 | 250 | 315 | ||

2.5 | 85 | 106 | 132 | 170 | 212 | 265 | 335 | ||

22.4 | 45 | 1 | 63 | 80 | 100 | 125 | 160 | 200 | 250 |

1.5 | 75 | 95 | 118 | 150 | 190 | 236 | 300 | ||

2 | 85 | 106 | 132 | 170 | 212 | 265 | 335 | ||

3 | 100 | 125 | 160 | 200 | 250 | 315 | 400 | ||

3.5 | 106 | 132 | 170 | 212 | 265 | 335 | 425 | ||

4 | 112 | 140 | 180 | 224 | 280 | 355 | 450 | ||

4.5 | 118 | 150 | 190 | 236 | 300 | 375 | 475 | ||

45 | 90 | 1.5 | 80 | 100 | 125 | 160 | 200 | 250 | 315 |

2 | 90 | 112 | 140 | 180 | 224 | 280 | 355 | ||

3 | 106 | 132 | 170 | 212 | 265 | 335 | 425 | ||

4 | 118 | 150 | 190 | 236 | 300 | 375 | 475 | ||

5 | 125 | 160 | 200 | 250 | 315 | 400 | 500 | ||

5.5 | 132 | 170 | 212 | 265 | 335 | 425 | 530 | ||

6 | 140 | 180 | 224 | 280 | 355 | 450 | 560 | ||

90 | 180 | 2 | 95 | 118 | 150 | 190 | 236 | 300 | 375 |

3 | 112 | 140 | 180 | 224 | 280 | 355 | 450 | ||

4 | 125 | 160 | 200 | 250 | 315 | 400 | 500 | ||

6 | 150 | 190 | 236 | 300 | 375 | 475 | 600 | ||

8 | 170 | 212 | 265 | 335 | 425 | 530 | 670 | ||

180 | 355 | 3 | 125 | 160 | 200 | 250 | 315 | 400 | 500 |

4 | 140 | 180 | 224 | 280 | 355 | 450 | 560 | ||

6 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||

8 | 180 | 224 | 280 | 355 | 450 | 560 | 710 | ||

表6 螺紋旋合長度

單位:微米 | ||||||

基本大徑 D、d | 螺距 P | 旋合長度 | ||||

S | N | L | ||||

> | ≤ | ≤ | > | ≤ | > | |

0.99 | 1.4 | 0.2 | 0.5 | 0.5 | 1.4 | 1.4 |

0.25 | 0.6 | 0.6 | 1.7 | 1.7 | ||

0.3 | 0.7 | 0.7 | 2 | 2 | ||

1.4 | 2.8 | 0.2 | 0.5 | 0.5 | 1.5 | 1.5 |

0.25 | 0.6 | 0.6 | 1.9 | 1.9 | ||

0.35 | 0.8 | 0.8 | 2.6 | 2.6 | ||

0.4 | 1 | 1 | 3 | 3 | ||

0.45 | 1.3 | 1.3 | 3.8 | 3.8 | ||

2.8 | 5.6 | 0.35 | 1 | 1 | 3 | 3 |

0.5 | 1.5 | 1.5 | 4.5 | 4.5 | ||

0.6 | 1.7 | 1.7 | 5 | 5 | ||

0.7 | 2 | 2 | 6 | 6 | ||

0.75 | 2.2 | 2.2 | 6.7 | 6.7 | ||

0.8 | 2.5 | 2.5 | 7.5 | 7.5 | ||

5.6 | 11.2 | 0.75 | 2.4 | 2.4 | 7.1 | 7.1 |

1 | 3 | 3 | 9 | 9 | ||

1.25 | 4 | 4 | 12 | 12 | ||

1.5 | 5 | 5 | 15 | 15 | ||

11.2 | 22.4 | 1 | 3.8 | 3.8 | 11 | 11 |

1.25 | 4.5 | 4.5 | 13 | 13 | ||

1.5 | 5.6 | 5.6 | 16 | 16 | ||

1.75 | 6 | 6 | 18 | 18 | ||

2 | 8 | 8 | 24 | 24 | ||

2.5 | 10 | 10 | 30 | 30 | ||

22.4 | 45 | 1 | 4 | 4 | 12 | 12 |

1.5 | 6.3 | 6.3 | 19 | 19 | ||

2 | 8.5 | 8.5 | 25 | 25 | ||

3 | 12 | 12 | 36 | 36 | ||

3.5 | 15 | 15 | 45 | 45 | ||

4 | 18 | 18 | 53 | 53 | ||

4.5 | 21 | 21 | 63 | 63 | ||

45 | 90 | 1.5 | 7.5 | 7.5 | 22 | 22 |

2 | 9.5 | 9.5 | 28 | 28 | ||

3 | 15 | 15 | 45 | 45 | ||

4 | 19 | 19 | 56 | 56 | ||

5 | 24 | 24 | 71 | 71 | ||

5.5 | 28 | 28 | 85 | 85 | ||

6 | 32 | 32 | 95 | 95 | ||

90 | 180 | 2 | 12 | 12 | 36 | 36 |

3 | 18 | 18 | 53 | 53 | ||

4 | 24 | 24 | 71 | 71 | ||

6 | 36 | 36 | 106 | 106 | ||

8 | 45 | 45 | 132 | 132 | ||

180 | 355 | 3 | 20 | 20 | 60 | 60 |

4 | 26 | 26 | 80 | 80 | ||

6 | 40 | 40 | 118 | 118 | ||

8 | 50 | 50 | 150 | 150 | ||

表7 内螺紋推薦公差帶

公差精度 | 公差帶位置 G | 公差帶位置 H | ||||

S | N | L | S | N | L | |

精密 | / | / | / | 4H | 5H | 6H |

中等 | (5G) | 6G | (7G) | 5H | 6H | 7H |

粗糙 | / | (7G) | (8G) | / | 7H | 8H |

表8 外螺紋推薦公差帶

公差精度 | 公差帶位置 e | 公差帶位置 f | 公差帶位置 g | 公差帶位置 h | ||||||||

S | N | L | S | N | L | S | N | L | S | N | L | |

精密 | / | / | / | / | / | / | / | (4g) | (5g4g) | (3h4h) | 4h | (5h4h) |

中等 | / | 6e | (7e6e) | / | 6f | / | (5g6g) | 6g | (7g6g) | (5h6h) | 6h | (7h6h) |

粗糙 | / | (8e) | (9e8e) | / | / | / | / | 8g | (9g8g) | / | / | / |

30°楔形防松螺紋

小螺紋 :牙型、系列和基本尺寸

普通螺紋搓制和滾制前的毛坯直徑

60°密封管螺紋(NPT錐管螺紋)

60°幹密封管螺紋 (ASME B1.20.3:1976,MOD)

鋼絲螺套用内螺紋

鋸齒形(30°, 3°)螺紋 - 第1部分: 牙型

米制密封螺紋

普通螺紋 極限尺寸

統一螺紋 直徑與牙數系列

梯形螺紋 第1部分:牙型

普通螺紋 管路系列

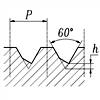

普通螺紋 基本牙型 (ISO 68-1:1998, MOD)

普通螺紋 基本尺寸

普通螺紋 極限偏差

普通螺紋 優選系列

普通螺紋 中等精度、優選系列的極限尺寸

普通螺紋 粗糙精度、優選系列的極限尺寸

自攻螺釘用螺紋

55°非密封管螺紋 (eqv ISO 228-1:1994)

55° 密封管螺紋 - 圓柱内螺紋與圓錐外螺紋 (eqv ISO 7-1:1994)

55°密封管螺紋 圓錐内螺紋與圓錐外螺紋 (eqv ISO 7-1:1994)

過盈配合螺紋

普通螺紋收尾、肩距、退刀槽和倒角 (ISO 3508:1976 / ISO 4755:1983)

過渡配合螺紋

用螺紋密封的管螺紋

自攻鎖緊螺釘的螺杆(三角鎖緊螺紋)

木螺釘技術條件

米制自切自攻螺紋尾端

米制自攻螺紋尾端

錐度1:16 管牙R牙

塑料牙螺紋

AB和B型自攻螺紋

ISO - 公制梯形螺紋

木螺釘 - 螺紋及末端

帶縮徑杆的螺栓連接件 帶大間隙的米制螺紋 标稱尺寸和極限尺寸

航空航天 引導和收尾螺紋 第1部分: 滾壓外螺紋

梯形螺紋:基本和設計牙型

一般用途米制螺紋公差Part1:原則和基本數據

緊固件的公稱長度和螺紋長度

ISO英制螺紋 基本尺寸

非螺紋密封連接的管螺紋 G管螺紋

自攻螺紋

普通螺紋 直徑與螺距系列

ISO通用公制螺紋 螺釘、螺栓和螺母的選擇尺寸

ISO一般用途米制螺紋--公差 part2:内螺紋和外螺紋的極限尺寸

ISO一般用途米制螺紋 公差Part3:結構螺紋的偏差

螺紋上采用壓力密封接頭的管螺紋 第1部分:尺寸、公差和名稱

ISO一般用途米制螺紋 基本尺寸

淺螺紋(HA型) [Figure 2]

深螺紋(HB型) [Figure 4]

HC螺紋 [Figure 4]

HD螺紋 [Figure 6]

自攻螺紋及尾端

公制螺紋極限量規

自攻螺紋及尾端

錐形管螺紋

米制粗螺紋的尺寸和公差限值

自攻螺紋及尾端

30°楔形防松螺紋

搓(滾)制普通螺紋前的毛坯直徑

光學儀器特種細牙螺紋

![AB型和ABR型自攻螺紋和末端 [Table 40]](https://imgcc.164580.com/upload/48/standard/2018/09/28/1538121933855296516.jpg)

AB型和ABR型自攻螺紋和末端 [Table 40]

![B型 BP型自攻螺釘螺紋和末端 [Table 41]](https://imgcc.164580.com/upload/48/standard/2018/09/29/1538186661945324758.jpg)

B型 BP型自攻螺釘螺紋和末端 [Table 41]

![A型自攻螺釘螺紋和末端 [Table 42]](https://imgcc.164580.com/upload/48/standard/2018/09/29/1538199242541614227.jpg)

A型自攻螺釘螺紋和末端 [Table 42]

A、AB、B、BF、BP以及BT型自攻螺釘的螺紋長度 [Table 46]

C, D, F, G, T 以及TRS型自攻螺釘的螺紋長度 [Table 47]

![Lag 木螺紋 [Table 16]](https://imgcc.164580.com/upload/48/standard/2012/02/03/1328254371610499842.jpg)

Lag 木螺紋 [Table 16]

AB自攻牙

B型 自攻牙

BF型 自攻牙

D型 自切自攻螺紋

BP型 自攻牙

BT型 自攻牙

T型 自攻自切螺釘

F型 自攻自切螺釘

螺紋杆(統一螺紋) (A307, F1554, A193, CRES,F593,F468)

![木螺紋 [Table 1]](https://imgcc.164580.com/upload/48/standard/2011/07/29/1311927213993228307.jpg)

木螺紋 [Table 1]

![木螺紋 [Table 1]](https://imgcc.164580.com/upload/48/standard/2011/04/29/1304063562598941856.jpg)

木螺紋 [Table 1]

![木螺釘螺紋及杆徑 [Table 1]](https://imgcc.164580.com/upload/48/standard/2024/12/23/1734937527164073998.jpg)

木螺釘螺紋及杆徑 [Table 1]

電纜管理用導管系統 - 電氣安裝導管的外徑及導管和配件的螺紋

有壓力緊固連接件的管道螺紋 第1部分:錐形外螺紋和平行内螺紋-尺寸、公差和名稱

高低牙自攻螺紋

美制三角鎖緊螺紋S型

米制三角鎖緊螺紋S型

米制三角鎖緊螺紋C型

米制三角鎖緊螺紋B型

米制三角鎖緊螺紋P型

![英制Y型切削螺紋 [TABLE 6]](https://imgcc.164580.com/upload/48/standard/2020/07/27/1595832347314908017.jpg)

英制Y型切削螺紋 [TABLE 6]

![英制A型自攻螺紋 [TABLE 23]](https://imgcc.164580.com/upload/48/standard/2020/07/27/1595832360911151243.jpg)

英制A型自攻螺紋 [TABLE 23]

塗膠自攻螺套推薦長度

螺紋-UNJ型,英制

尼龍鎖緊用自攻螺紋

自攻螺紋

普通螺紋 直徑與螺距系列

A、AB、B、BF、BP和BT型自攻螺釘頭下肩距

C、D、F、G、T和TRS型自攻螺釘的頭下肩距

AB、ABR型自攻螺釘螺紋和末端

B型 BP型自攻螺釘螺紋和末端

A型自攻螺釘螺紋和末端